About CPR - Complete Pipe Repair Experts

At CPR - Complete Pipe Repair, we are the industry leaders in cured-in-place pipe lining, utilizing scientifically advanced products and methods. Our commitment to operating with integrity, delivering consistent, proven results, and offering affordable solutions has made us your trusted local drainage specialist.

Send Us a Message

"*" indicates required fields

Our Three-Step Process

1. Investigate

We utilize HDR video inspection to diagnose the issue, allowing us to clearly locate any problem areas within your pipes.

2. Clean

Our high-powered jets restore pipes to their original diameter by removing all buildup and roots.

3. Solve

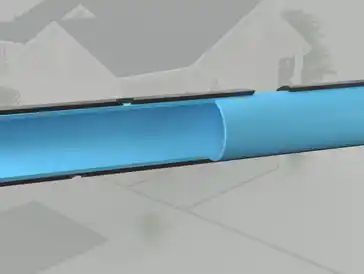

We install a new pipe within the existing pipe, eliminating any need for digging, demolition, or disruption to your property.

FAQ

CIPP lining, or cured-in-place pipe lining, is a method of pipe restoration used in existing pipe repair. This process is done to preserve current pipes that have been damaged by leaks, cracks, intruding roots, and rust. It increases the lifespan of a pipe system while also possibly preserving building structures and causing little to no damage to property.

Here are some frequently asked questions to help you decide whether CIPP lining is right for you:

First - We inspect the pipelines using an HD video camera. This allows us to not only measure the pipe but also see the extent of the damage. After the inspection is completed, we create an action plan to repair all pipe problems.

Second - Once we properly assess the damage and propose a solution, we thoroughly clean the lines using a high-pressure water Jetter and special tools to remove fat, oil, grease, dirt, mud, tree roots, debris, and other objects that are clogging up the system.

Third - After the pipe is cleaned that's when we start the process of lining the pipe. We pull a new CIPP liner in place and saturate it with an epoxy cure. The liner will then inflate, causing the pipe to cure in place. The result is the creation of a strong, smooth, and seamless 'pipe within a pipe'.

Not all pipe problems are noticeable right away. In fact, it's more common for issues to be spotted long after a sewer or drain line has been damaged to some extent. This is often the case with tree root intrusions. That said, there are some signs we recommend looking out for that suggest CIPP may be right for your situation. These include:

- Unusually soggy or green spots on your lawn

- Damage around or to your foundation

- Issues with more than one drain in your home – including frequent clogs and backups

- Persistent and sometimes strong odors coming from drain or sewer lines

- Pest and/or rodent problems

- Rising water bills

CIPP is a highly flexible process in that it can address a wide range of common issues. These include cracks from soil shifting or age, as well as damage from corrosion, tree roots, and general deterioration from normal wear. In some instances, small gaps in pipes may also be filled with the liner once the resin hardens.

Many older properties have cast iron pipes that have been in place for several decades. If the pipe is still structurally stable, it's often possible to strengthen older cast iron pipes with a new resin coating to provide many more years of safe, reliable use.

Our CIPP lining system can be installed in vertical and horizontal pipes. CIPP liner can even be installed inside asbestos-covered pipes or inside architectural stone pipes.

Yes. The liner can be inserted through a cleanout or from a small excavation point. Since the end of the liner is open, there is no need to access the other end of the liner.

Yes. Since the process of cured-in-place pipe lining is done using the "zero-dig" method, meaning it doesn't require the process of excavation, it falls into the category of a trenchless pipe lining method.

There is a minimal reduction in diameter, but the smooth interior of the cured-in-place pipe typically improves the flow rate. Also, since the pipe is pre-cleaned before the lining process begins, it typically removes the gunk that has been restricting the flow.

Our cured-in-place pipe lining technicians are experts at creating pipes that are built to stand the test of time. The epoxy resin coating applied to the pipe system provides a damp-proof, corrosion-resistant, wear-resistant, and non-corrosive lining. This lining ensures that the system is completely protected and strengthened to last for decades.

On average, a CIPP liner can last up to 100 years. With average use, the new pipe lining will be protected against any root intrusion, cracks, leaks, and other damages associated with underground utilities.

The cost savings to CIPP repair has both short and long-term advantages. The streamlined installation process reduces the cost of labor associated with traditional pipe repair. And, without the labor costs of digging, CIPP repair is much more inexpensive. Additionally, paving and restorative landscaping is usually needed after digging. This is one of the most expensive parts of pipe repair when you use excavation methods.

With CIPP repair, any pipe repair needed can be fixed. Age deterioration, root, or plant intrusion, cracking and fracturing, corrosion, and damage from a faulty installation are the leading causes of pipe damage. This leaves a huge range of issues that could need to be repaired. CIPP has the advantage of being able to repair virtually any kind of pipe. Multiple angles and bends don’t hinder effectiveness. And even large buildings, municipal pipe systems, and complex sewer systems benefit from CIPP repair.

Yes. The process of CIPP restoration is completed in a matter of hours or days instead of over a longer period. This noninvasive alternative to traditional pipe repair leads to less overhead, lower costs, and a more efficient way to solve the problem without creating chaos.

Epoxy Lining can be used to rehabilitate virtually any type of pipe, including damaged concrete, PVC, fiberglass, clay, cast iron, and ductile iron pipelines and field use such as vertical vent pipes, sanitary waste, roof drains, chiller lines, underground storm and sewer lines, transmission lines, fire suppression lines, and even underground tunnel and conduit systems.

Hopefully, these helped answer some of your questions about cured-in-place pipe lining, and you feel more confident in this being your choice for your pipe repair needs.